EMI EL-SQRD

EMI EL-SQRD

Contact us for price

Location:Little Rock, AR

Description

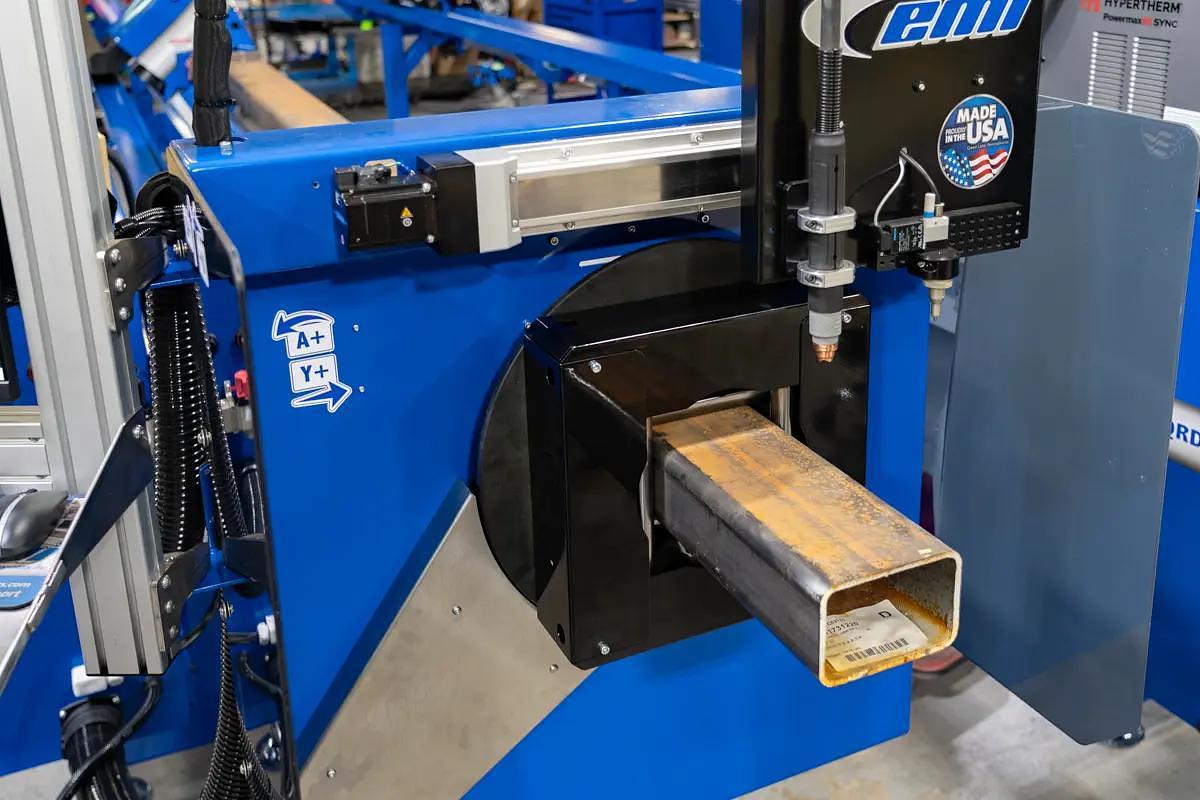

Cost-Effective Multi-Profile Plasma Cutting with Manual Loading

- Cut, Miter, Cope, Mark, Burn Holes & Slots

- Round stock up to 6.625”

- Square & Rectangle stock up to 6” x 6”

- Channel stock up to C6 x 13lbs

- Angle stock up to 6” x 6”

- Flat stock up to 8″

CNC Tube Plasma Cutting You Can Count On

Our EL-SQRD CNC tube plasma cutting system gives fabricators the perfect stepping stone to the benefits of CNC automation. Thanks to robust build quality, smart design, and easy programming, the EL-SQRD will help you ramp up production of tube, pipe, angle, channel and miscellaneous metals with ease.

For fabricators who are new to CNC cutting and automation, the EL-SQRD comes standard with our proprietary Piecemaker software. This intuitive software was designed by fabricators for fabricators, and allows you to quickly program the machine right at the machine simply by inputting a few data points right off the drawing.

For more advanced shops, the EL-SQRD optionally integrates with the Lantek Flex 3D system. This allows the machine to connect directly into the latest shop management software, and import just about any industry-standard file type.

Key Features & Benefits of the EL-SQRD

- Process Round, Square, Rectangle, Channel, Angle and Flat Stock

- Save Time by Combining Multiple Processes Into a Single Step

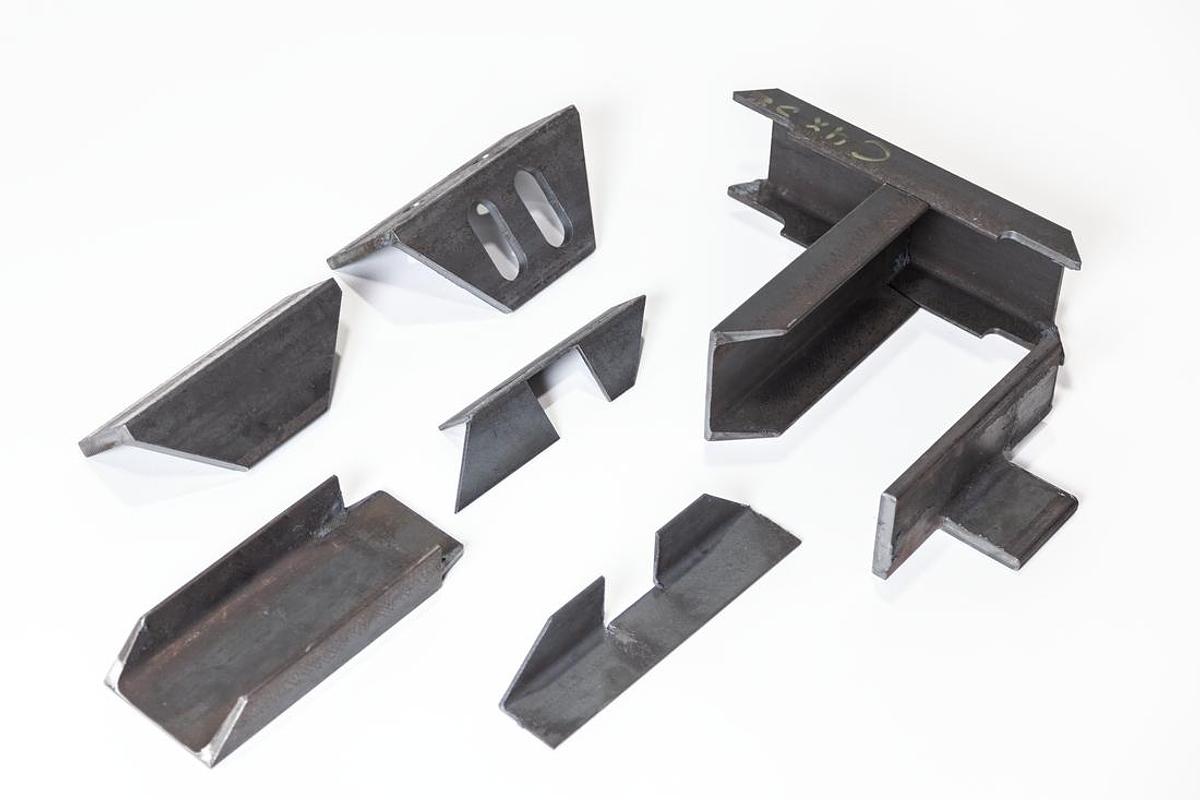

- Cut, Miter, Cope, Mark, Burn Holes and Slots

- Cut Any Combination of Diameters and Intersection Angles With No Tooling Changes

- Eliminate Manual Measuring, Sawing, Notching, Drilling and Deburring

- Eliminate Repetitive Material Handling and Downstream Processes

- Produce Weld-Ready Miters and Copes Right From the Machine

- Significantly Improve Fit-Up and Weld Penetration

- Save Substantial Time Producing the Parts You Need

- Additional Features

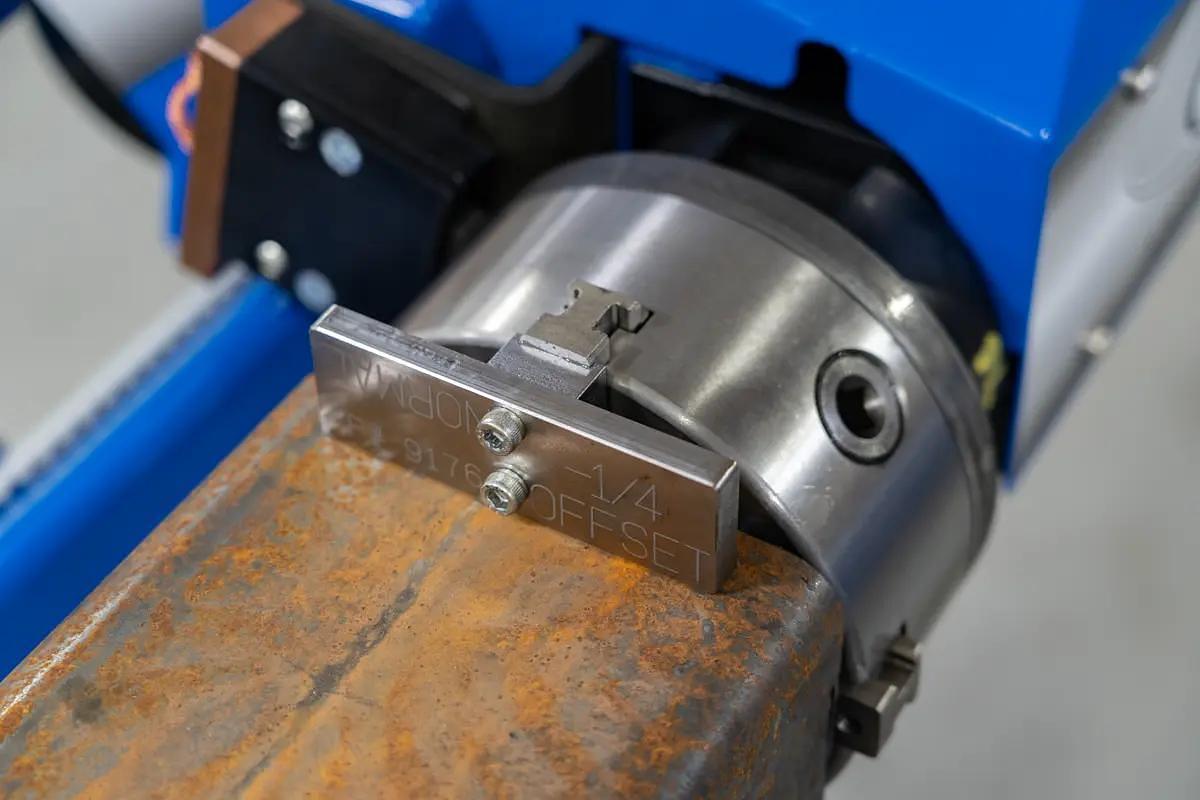

- Closed-Loop Servo Motors for Best-In-Class Accuracy and Repeatability

- Breakaway Torch Prevents Costly Downtime

- Self-Centering Front Support for Easy Material Changeover

- Universal Front Material Support Reduces Time Switching From One Profile to the Next

- Automatic Material Supports Make Loading a Breeze

- Specifications

- Processes

- Cuts

- Miters

- Copes

- Marks

- Burns Holes & Slots

- Material Sizes

- Round stock up to 6.625”

- Square & Rectangle stock up to 6” x 6”

- Channel stock up to C6 x 13lbs

- Angle stock up to 6” x 6”

- Flat stock up to 8”

- Plasma System Options

- Hypertherm Powermax105 SYNC

- Hypertherm Powermax85 SYNC (standard)

- Material Length

- Maximum 24’

- Full Stick Load Capacity

- Maximum 20 lbs / ft

- Max Work Piece Weight

- 480 lbs

- Machine Footprint

- 337″ long, 64″ wide

- Power Requirements

- Machine Cabinet Requirements

- 220VAC, 25A 1-PH

- Hypertherm Requirements

- Varies based on Powermax model

Specifications

| Manufacturer | EMI |

| Model | EL-SQRD |

| Condition | New |

| Stock Number | Factory |